Hot Water Systems:

Sioux NexGen water heaters are advanced, high-efficiency water heating systems designed to provide reliable and consistent hot water for residential and commercial use. These water heaters feature cutting-edge technology that ensures rapid heating, energy savings, and long-lasting performance. The NexGen series incorporates durable materials and innovative engineering to minimize heat loss and optimize energy consumption, making them environmentally friendly and cost-effective. With easy installation and maintenance, Sioux NexGen water heaters are ideal for users seeking modern solutions for their hot water needs.

Cold Water Systems:

Sioux chilled water systems for concrete are specialized cooling solutions designed to control the temperature of concrete during mixing and curing processes. These systems use chilled water to regulate the heat generated by the hydration reaction of cement, helping to prevent overheating, which can lead to reduced strength and durability of the concrete.

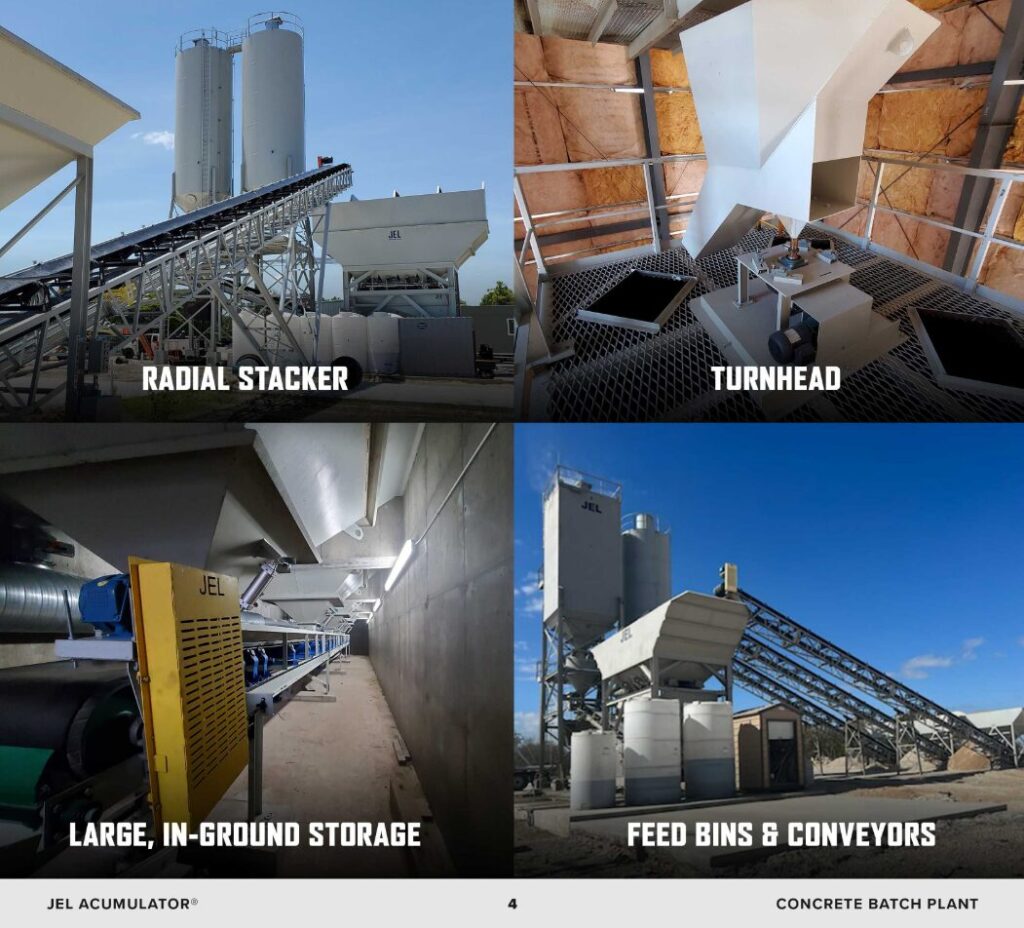

Conveyors:

JEL conveyors are robust, custom-built conveyors used primarily in concrete batch plants for moving and transferring raw materials such as sand, gravel, and cement between storage bins, mixers, and other processing units.

Reclaimers:

BFK Reclaimers are specialized machines designed to efficiently remove and reclaim concrete materials from construction and demolition sites. They work by breaking down hardened concrete into reusable aggregate, which can then be recycled for new concrete production or other construction applications.

This process helps reduce waste, lower material costs, and promote sustainable construction practices by minimizing the need for virgin raw materials. BFK Reclaimers typically feature powerful crushers, screens, and conveyors to separate and process concrete debris, ensuring high-quality reclaimed material suitable for various uses.

Cement and Flyash Silos:

Cement and Flyash Silos are specialized storage structures designed to store bulk materials like cement and flyash safely and efficiently. These silos are typically constructed from high-quality steel and are engineered to protect the materials from moisture, contamination, and environmental factors.

Dust Collection Systems:

With their wide range of Silo Venting Filters, WAMGROUP has become the world market leader thanks to continuous technical improvement of the product and dedicated research in the area of dust filtration technology.

Learn more about C&W Dust Collector systems:

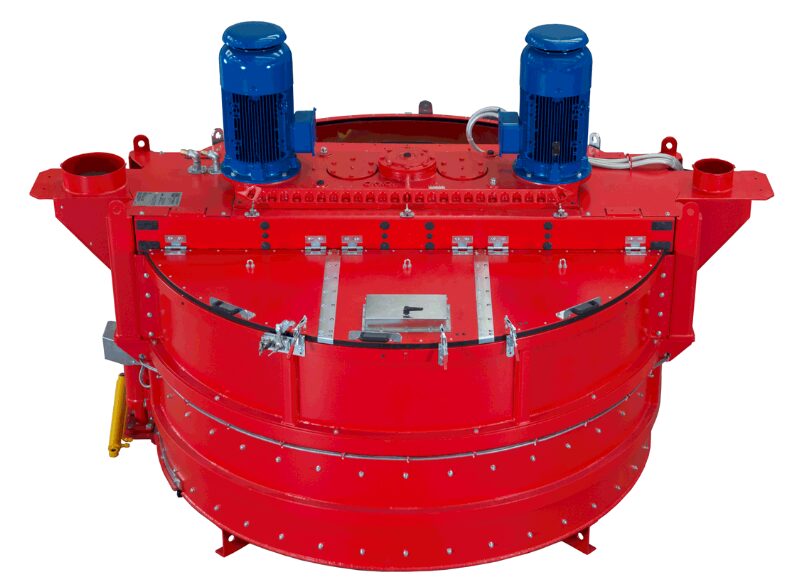

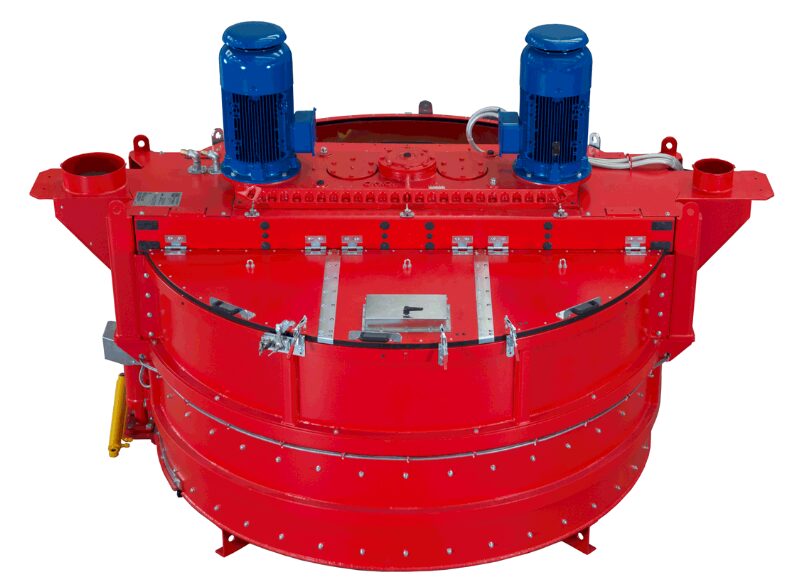

Planetary Mixers:

Planetary mixers are industrial mixing machines designed for thorough blending of materials. They feature a central mixing bowl with one or more mixing tools that rotate on their own axis while simultaneously revolving around the bowl’s center, resembling the motion of planets—hence the name. This dual motion ensures uniform mixing, making planetary mixers ideal for applications involving viscous substances, doughs, pastes, and creams. They are widely used in bakeries, chemical processing, pharmaceuticals, and cosmetics industries. The design allows for efficient mixing of heavy and thick materials without damaging the ingredients.

Twin Shaft Mixers:

Twin shaft mixers consist of two horizontally mounted shafts equipped with mixing paddles or blades that rotate in opposite directions. This counter-rotating action creates a highly turbulent mixing environment, enabling rapid and homogeneous blending of materials. Twin shaft mixers are particularly effective for mixing dry powders, granules, and even some wet materials. They are commonly used in construction, pharmaceuticals, food production, and chemical industries. These mixers excel in handling large volumes and providing consistent mixing results in a relatively short time, making them suitable for high-capacity industrial processes.

Keystone Dispatch Batch Computers:

Keystone Dispatch is a specialized logistics and transportation service designed to support cement plants by efficiently managing the delivery and distribution of raw materials and finished products. It focuses on optimizing routes, scheduling shipments, and ensuring timely dispatch to maintain continuous production flow and meet customer demands. Keystone Dispatch integrates advanced tracking and communication systems to provide real-time updates, improve operational efficiency, and reduce downtime in cement plant operations.

Screw Conveyor:

As a specialized version of the modular TU Screw Conveyor, ES Screw Conveyors and Feeders are manufactured from carbon steel with suitable surface finishing and powder coating. They are made up from a tubular trough equipped with at least one inlet and outlet spout, a welded flange at each tube end, heticoid screw flighting welded on a center pipe with coupling bush at each end, two-end bearing assemblies complete with self-adjusting shaft seal. (One of the bearing assemblies is integrated into the drive unit), and a number of intermediate hangar bearings, depending on the overall length. ES Screw Conveyors and Feeders are equipped with a gear motor that suits the application.

Truck Wash:

SIOUX TRUCK WASH: Innovative Wash System for Ready Mix Trucks